General Insights on UL Panel Fabrication

With the recent developments in electrical and electronic systems, many advanced technologies are used in commercial as well as industrial applications. UL panels are one of the greatest innovations of decades which find solutions for various demands in present as well as future attributes. Many top providers are offering wide ranges of UL panel fabrication at different qualities to meet the demands in many industries. Thus, finding such providers are certainly important to gain positive effects from any lag of operations. Moreover, now provisions are available where seekers can get their customized design provisions through which one can get suitable products with special purposes. However, keen insights are essential to know about the manufacturer's process and effectiveness.

Basic conception

Generally, before undertaking customization of their products, one should know about it in detail. These types of panels are highly recognized for ICP which is defined as national electrical code sections that are integrated with two or more power circuit components and control circuits. It is available in the form of switches, contactors, boards, motors, transformers as well as protection appliances, etc. Apart from this, it is available as both open and closed type procedures where equipment is completely implanted to make sure of being used in actual services.

Thus, there are lots of regulations that are followed in manufacturing particular panels for a particular usage. It can be either built as mass-produced or custom-built ICP without involving in tests on each design. This is represented as a shop program that gives extended flexibility on listing for manufacturers. It also covers certification and licensing to ensure its quality.

Needs for UL panels

Safety is the main concerns that help fabricators to govern their products. Generally, there is no essential way for each product which is tested by electrical executers. Moreover, it should become under minimal safety requirements which are highly possible through special inspection methodologies. General tests are made occasionally which has the possibility of reducing risk. This is a reason why UL panels are needed to be integrated through which working performance and regulations are perfectly checked in all essential aspects.

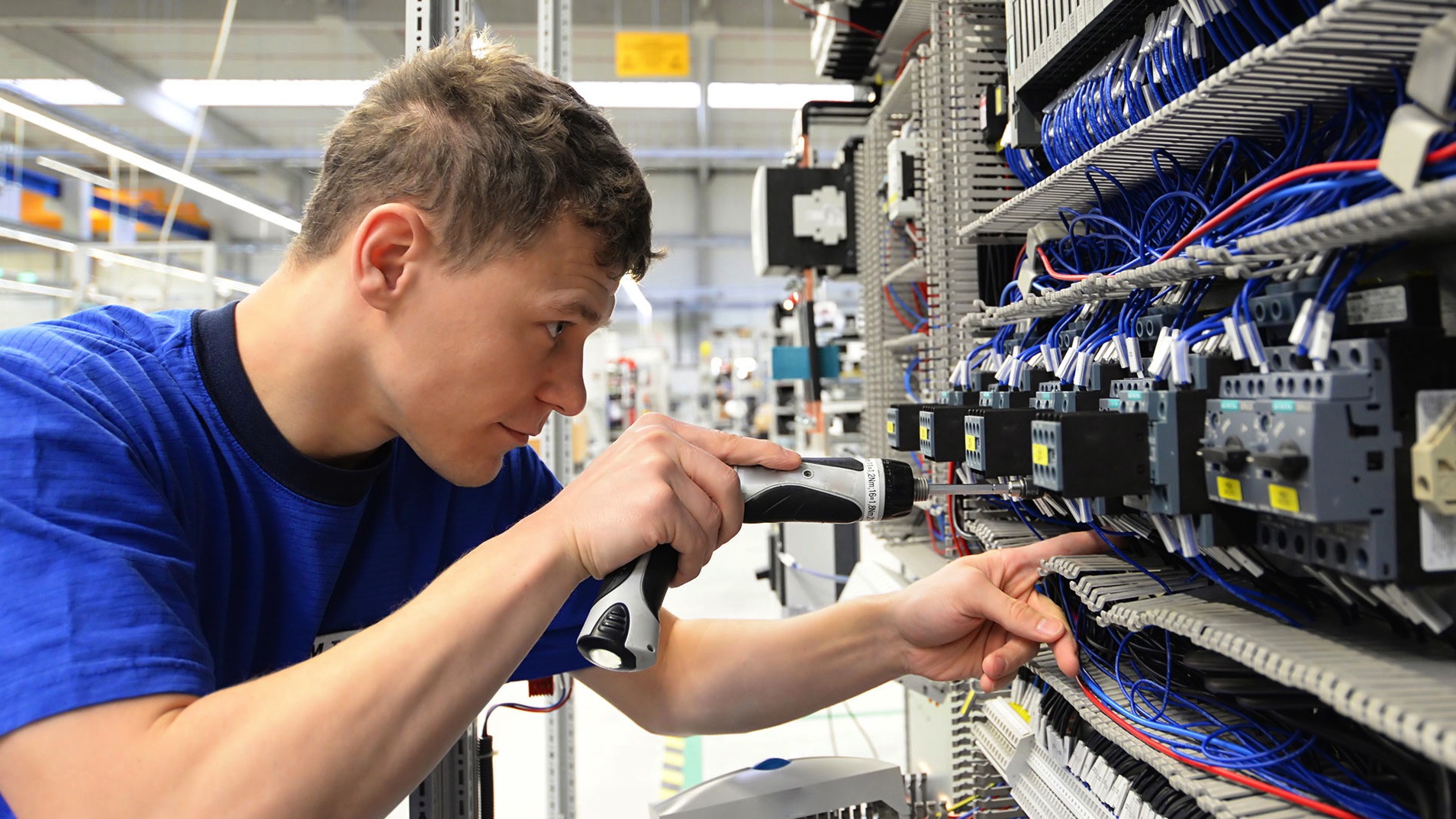

Fabrication from the best hands

When it comes to product, getting aid from quality service providers are certainly important. There are complete methodologies through which one can give expected panels for a particular industry. It starts with functional programs where designs are made with an engineer or technician for making an overall plan. Layouts are prepared through computer integrated systems that minimize time and efforts from preparation. Imperative nature of components gets varied based on essentiality plus additional overcurrent appliances are installed. Quality and features may differ from the fabrication nature of one company to another.